The push for renewable energy sources has resulted in an increase in the use of solar energy. The solar industry has grown by nearly 50% in the last decade, thanks to federal incentives and strong commercial and industrial demand for clean energy.

As the solar industry grows, it’s worth looking into the solar industry’s backbone: solar panels.

This guide will explain the various solar panel types on the market today, their advantages and disadvantages, and which is best suited for specific use cases.

What Exactly is a Solar Panel?

Solar panels capture solar energy from the sun and convert it to electricity.

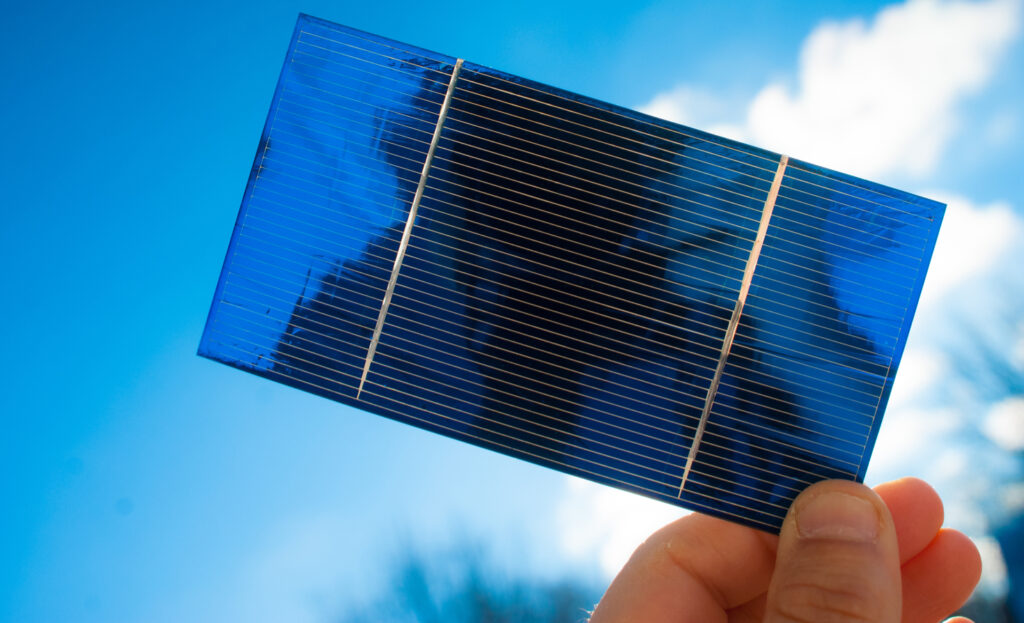

A typical solar panel is made up of individual solar cells that are made up of layers of silicon, boron, and phosphorus. The positive charge is provided by the boron layer, the negative charge is provided by the phosphorus layer, and the silicon wafer serves as the semiconductor.

When photons from the sun strike the panel’s surface, they knock electrons out of the silicon “sandwich” and into the electric field generated by the solar cells. This produces a directional current, which can then be converted into usable power.

Solar Panel Types: Solar Panels With A Single Crystal

These panels, also known as single-crystal panels, are created from a single pure silicon crystal that has been sliced into numerous wafers.

They are easily recognizable by their dark black hue because they are constructed of pure silicon. Monocrystalline panels are also the most space-efficient and long-lasting of the three solar panel types due to their usage of pure silicon.

Nevertheless, this comes at a cost: a significant amount of silicon is wasted in the production of a single monocrystalline cell, sometimes exceeding 50%. As a result, the price is high.

Solar Panel Types: Solar Panels Made Of Polycrystalline Crystals

As the name implies, these are made up of several silicon crystals rather than just one. Melted silicon pieces are poured into a square mould. This makes polycrystalline cells much more inexpensive because there is little waste, and it also gives them their distinctive square shape.

However, because their silicon purity and structure are lower than that of monocrystalline panels, they are less efficient in terms of energy conversion and space. They are also less heat tolerant, making them less efficient in high-temperature situations.

Solar Panel Types: PERC (Passivated Emitter And Rear Cell) Panels

PERC solar panels are another solar panel type, they are an advancement over conventional monocrystalline cells. This relatively new method adds a passivation layer to the cell’s back surface, which improves efficiency in various ways:

It returns light into the cell, increasing the amount of solar radiation absorbed. Also, it inhibits the flow of electrons in the system by reducing the natural inclination of electrons to recombine.

It enables the reflection of longer wavelengths of light. Light waves longer than 1,180nm cannot be absorbed by silicon wafers and instead flow through, heating the cell’s metal back sheet and reducing its efficiency.

The passivation layer reflects higher wavelengths, preventing them from heating up the back sheet.

PERC panels capture more solar energy in a smaller physical footprint, making them perfect for compact locations.

Because of the additional materials required, they are only slightly more expensive to build than standard panels, but they can be manufactured using the same equipment and can end up having a lower average cost per watt due to their efficiency.

Solar Panel Types: Thin-Film Solar Panels

Thin-film panels are distinguished by extremely tiny layers that are flexible. Because each panel does not need a frame backing, they are lighter and easier to install.

Unlike crystalline silicon panels, which come in preset sizes of 60, 72, and 96 cells, thin-film panels can be customized to meet unique demands. They are, however, less efficient than standard silicon solar panels.

Variations On Thin-Film Solar Panels

Thin-film solar panels, as opposed to crystalline panels, are built of different materials. They are as follows:

- Cadmium telluride (CdTe)

- Amorphous silicon (a-Si)

- Copper indium gallium selenide (CIGS)

Cadmium Telluride (CdTe)

CdTe provides the same low-cost advantage as polycrystalline cells while having the lowest carbon footprint, water need, and energy payback period of any solar panel type. Yet, because cadmium is hazardous, recycling it is more expensive than recycling other materials.

The Amorphous Silicon (a-Si)

Due to their shapeless nature, amorphous silicon panels (A-Si) get their name. Unlike monocrystalline and polycrystalline solar cells, silicon has no molecular structure.

On average, an a-Si cell takes only a quarter of the silicon required to create standard silicon cells. This allows them to have the lowest production cost at the sacrifice of efficiency. As a result, a-Si panels are ideal for low-power applications such as pocket calculators.

Copper Indium Gallium Selenide (CIGS)

A thin coating of copper, indium, gallium, and selenium is put on a glass or plastic backing to create CIGS panels. This combination produces the best efficiency among thin-panel varieties, albeit it is still not as efficient as crystalline silicon panels.

Looking to install any of the different solar panel types in your home or offices, contact us now